UNDERGROUND COPPER PROJECT

MINING FEASIBILITY STUDY IN ALASKA

Feasibility Study (FS) - Underground Copper Mine - Alaska

Drilling in the Ambler District

Roughstock was contracted to complete a Feasibility Study (FS) for a major Copper discovery in North-Central Alaska. The study included primary and secondary development of underground mine design, stope design, and infrastructure design for a planned 5,000 ton/day mine. Design work

and Life-of-Mine scheduling

was completed in Deswik Software. Primary development included a decline from surface, tie into existing shaft, and multiple ramp systems to the different ore-bodies. Mining methods included transverse long-hole stopes & cut and fill stopes.

SUMMARY

SERVICE(S)Mine Design, Geologic Services, Ventilation Design

TYPEUnderground Copper

SIZE5,000 tons per day

LOCATIONAlaska

SOFTWARE USEDDeswik Mine Design & Scheduling, VentSim Model.

Roughstock was contracted to complete a Feasibility Study (FS) for a major Copper discovery in North-Central Alaska. The study included primary and secondary development of underground mine design, stope design, and infrastructure design for a planned 5,000 ton/day mine. Design work

and Life-of-Mine scheduling

was completed in Deswik Software. Primary development included a decline from surface, tie into existing shaft, and multiple ramp systems to the different ore-bodies. Mining methods included transverse long-hole stopes & cut and fill stopes.

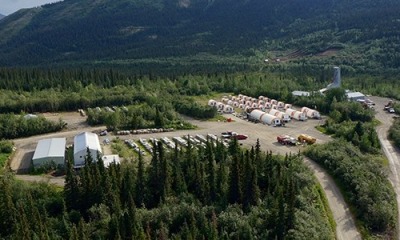

PROJECT PHOTOS

More Projects

Feasibility Study (FS) - Underground Zinc Mine - Arizona

Mine Management | Feasibility & QP | Vulcan Mine Design and Deswik Scheduling

Feasibility (FS) for major multi-metal mine in Southwestern Arizona.

Learn More

Preliminary Economic Assessment — Silver Mine — Idaho

Startup Assistance | Vulcan Software

Roughstock completed a preliminary economic assessment to help the startup of a mine in Idaho.

Learn More

Third Party Review — “Fill-the-Mill” Internal Feasibility Study (FS) -- Montana

Feasibility & QP | Vulcan and Deswik Software

Roughstock was asked to provide a third-party review of an internal FS being completed by a major PGM producer.

Learn More